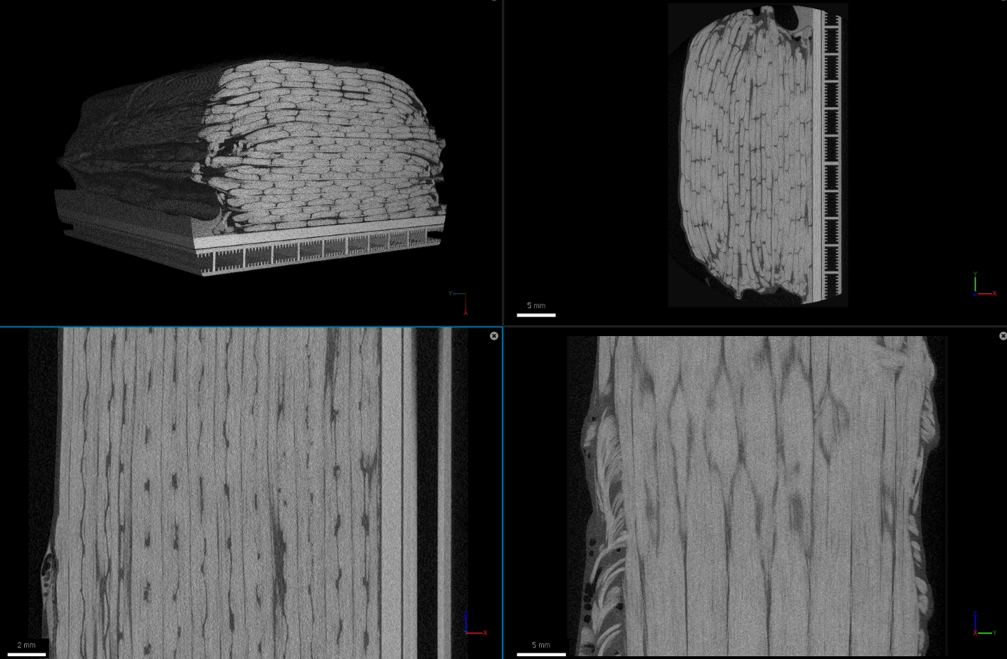

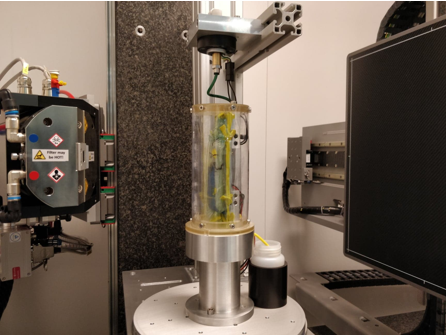

The stage was developed to inspect resin injection and curing of composite materials. The mini-composite lay-up of 40×80 mm and a thickness up to 20 mm is positioned on a light aluminum table and covered and sealed with a vacuum bag. During the dynamic scan the resin is pulled up in the matrix under vacuum pressure. The Curing stage is supported with the heating of the aluminum table. The curing process is monitored in another dynamic scan.

This stage was developed in cooperation with Sarah Gayot of UCLouvain and Arkema

Technical Details

Compatible with: TESCAN UniTOM XL

Room: Kasteelpark Arenberg 44, 3001 Leuven, Materials Engineering, X-ray lab: 91.15