Abstract

Abstract

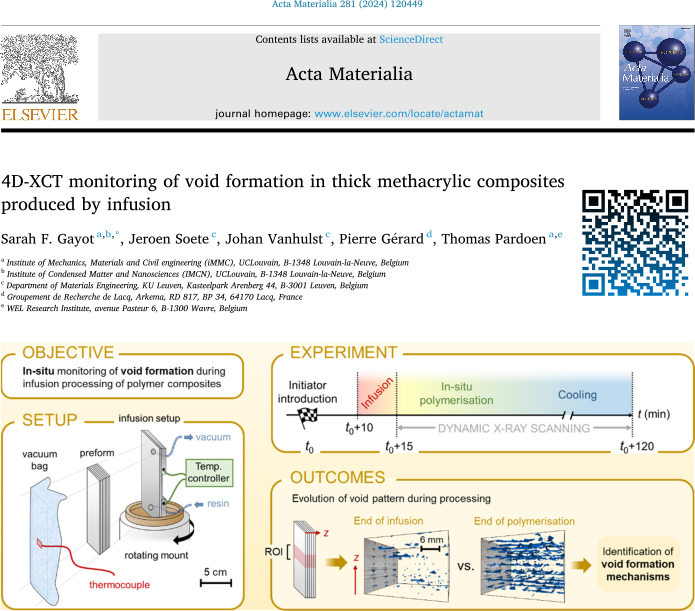

Void formation in fibre-reinforced polymer composites processed by liquid moulding is a persistent issue in composite research and development. Not only may several void formation mechanisms come into play, but these defects can also accumulate and grow over the course of the manufacturing process. Mitigation methods can be applied once the underlying causes of voiding are identified, which is impossible through post-mortem characterisation. Here, void formation is dynamically monitored in miniaturised glass fibre-reinforced thermoplastic polymer composite samples manufactured by vacuum infusion and in-situ polymerisation, using laboratory-based X-ray computed tomography (XCT). The method allows the characterisation of the evolution of void patterns as the resin polymerises and cools down within the fibre preform. With a time resolution of 2 min and a voxel size close to 20 µm, this first-of-a-kind XCT experiment provides insights into the evolution of the void volume fraction, void size and location. The root causes leading to void formation in the system of interest were successfully identified as a combination of flow-related air entrapment during preform filling and, mostly, of chemical shrinkage of the matrix upon polymerisation. Additionally, thermal shrinkage during the cooling of the preform results in a slight decrease in the final void volume fraction.