Abstract

Abstract

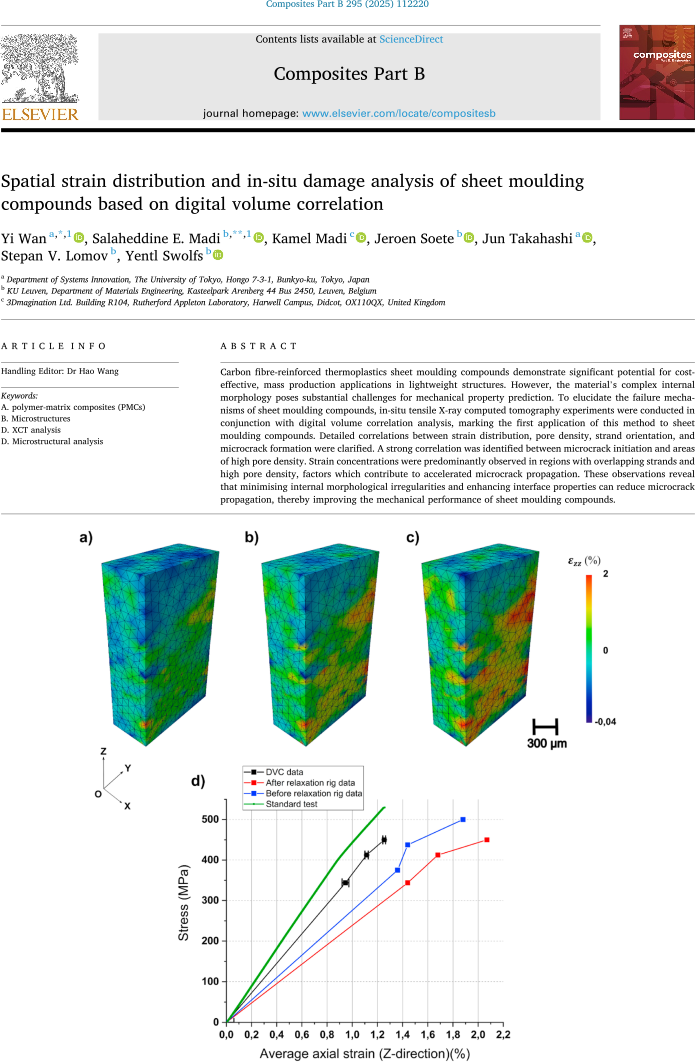

Carbon fibre-reinforced thermoplastics sheet moulding compounds demonstrate significant potential for cost-effective, mass production applications in lightweight structures. However, the material’s complex internal morphology poses substantial challenges for mechanical property prediction. To elucidate the failure mechanisms of sheet moulding compounds, in-situ tensile X-ray computed tomography experiments were conducted in conjunction with digital volume correlation analysis, marking the first application of this method to sheet moulding compounds. Detailed correlations between strain distribution, pore density, strand orientation, and microcrack formation were clarified. A strong correlation was identified between microcrack initiation and areas of high pore density. Strain concentrations were predominantly observed in regions with overlapping strands and high pore density, factors which contribute to accelerated microcrack propagation. These observations reveal that minimising internal morphological irregularities and enhancing interface properties can reduce microcrack propagation, thereby improving the mechanical performance of sheet moulding compounds.