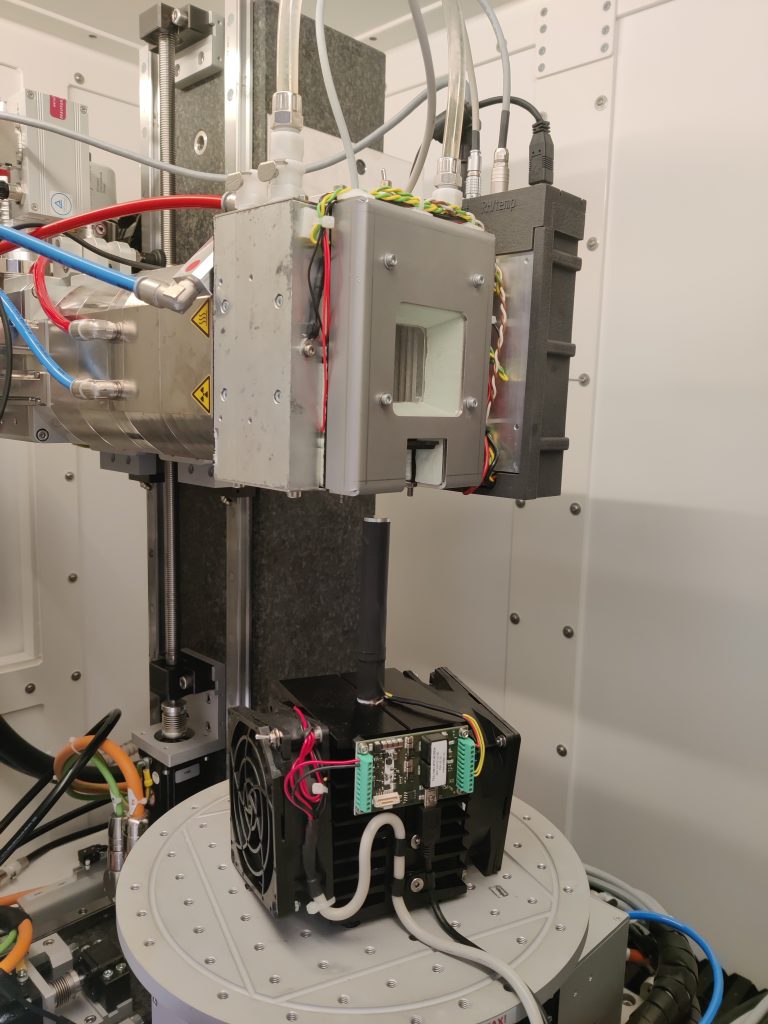

Our in-house designed heating and cooling stage, featuring a two part system: a temperature-controlled chamber and a bottom heater & cooler. This setup reaches temperatures in the range of -40ºC to 50ºC, enabling in-situ analysis under non-ambient conditions to study the effects of temperature on a sample’s microstructure.

Our in-house designed heating and cooling stage, featuring a two part system: a temperature-controlled chamber and a bottom heater & cooler. This setup reaches temperatures in the range of -40ºC to 50ºC, enabling in-situ analysis under non-ambient conditions to study the effects of temperature on a sample’s microstructure.

The versatile design allows researchers to choose between contact freezing, using the bottom cooler, or atmospheric freezing, using the cooling chamber, depending on the experimental requirements. The temperature controlled chamber can be flushed with nitrogen to prevent ice formation.

For moisture sensitive samples, the stage can maintain stable, low temperatures during scanning to prevent unwanted heating or dehydration and the associated structural changes to the microstructure.

The stage accommodates samples with a maximal sample diameter of 25 mm. For the scanning of larger samples under frozen conditions, we employ EPS (expanded polystyrene) containers equipped with tailored pockest for dry ice.

Technical Details

Compatible with: TESCAN UniTOM XL, TESCAN UniTOM HR, Nanotom M and Nanotom S

Room: Kasteelpark Arenberg 44, 3001 Leuven, Materials Engineering, X-ray lab: 91.15