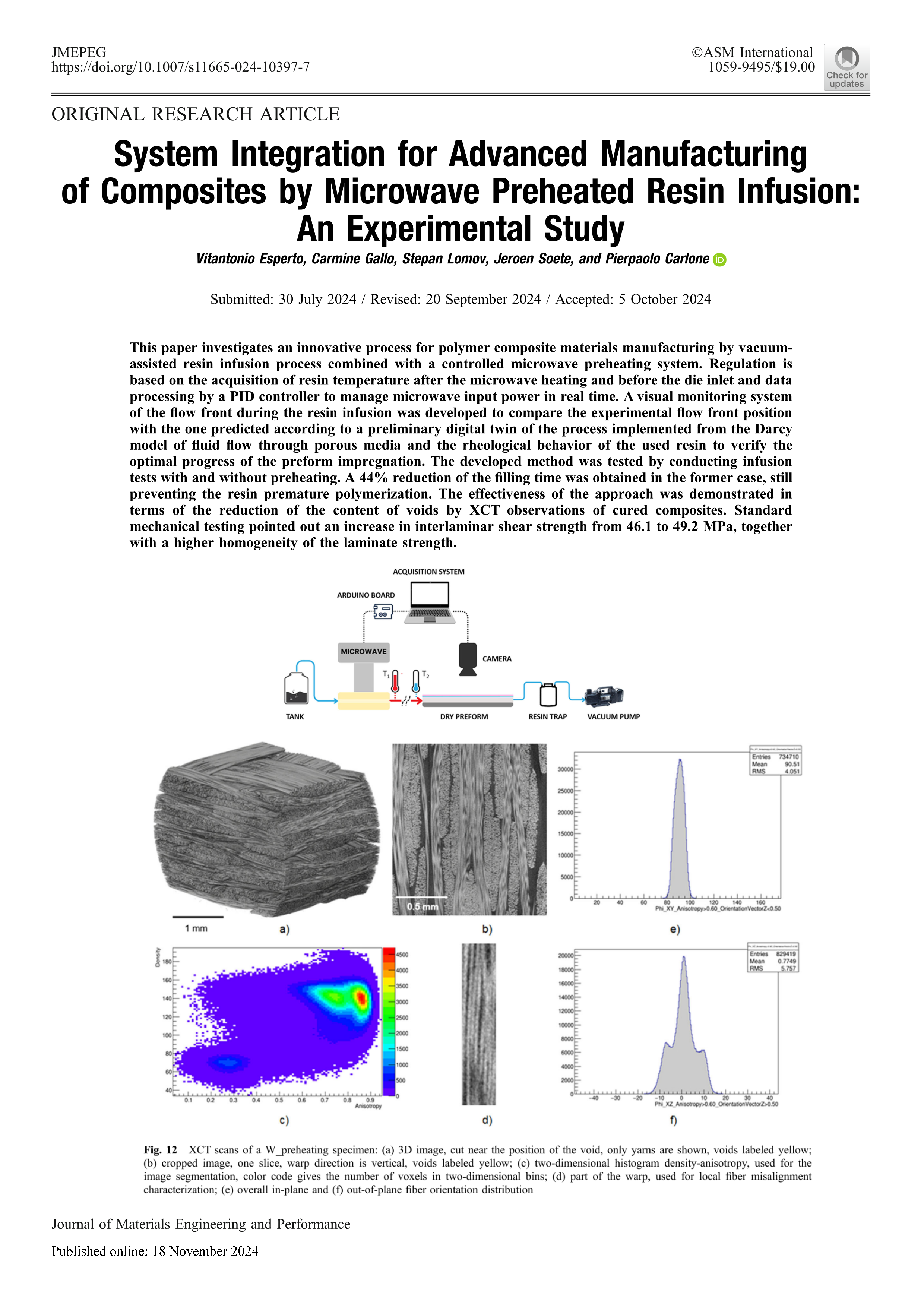

This paper investigates an innovative process for polymer composite materials manufacturing by vacuum-assisted resin infusion process combined with a controlled microwave preheating system. Regulation is based on the acquisition of resin temperature after the microwave heating and before the die inlet and data processing by a PID controller to manage microwave input power in real time. A visual monitoring system of the flow front during the resin infusion was developed to compare the experimental flow front position with the one predicted according to a preliminary digital twin of the process implemented from the Darcy model of fluid flow through porous media and the rheological behavior of the used resin to verify the optimal progress of the preform impregnation. The developed method was tested by onducting infusion tests with and without preheating. A 44% reduction of the filling time was obtained in the former case, still preventing the resin premature polymerization. The effectiveness of the approach was demonstrated in terms of the reduction of the content of voids by XCT observations of cured composites. Standard mechanical testing pointed out an increase in interlaminar shear strength from 46.1 to 49.2 MPa, together with a higher homogeneity of the laminate strength.