Abstract

Abstract

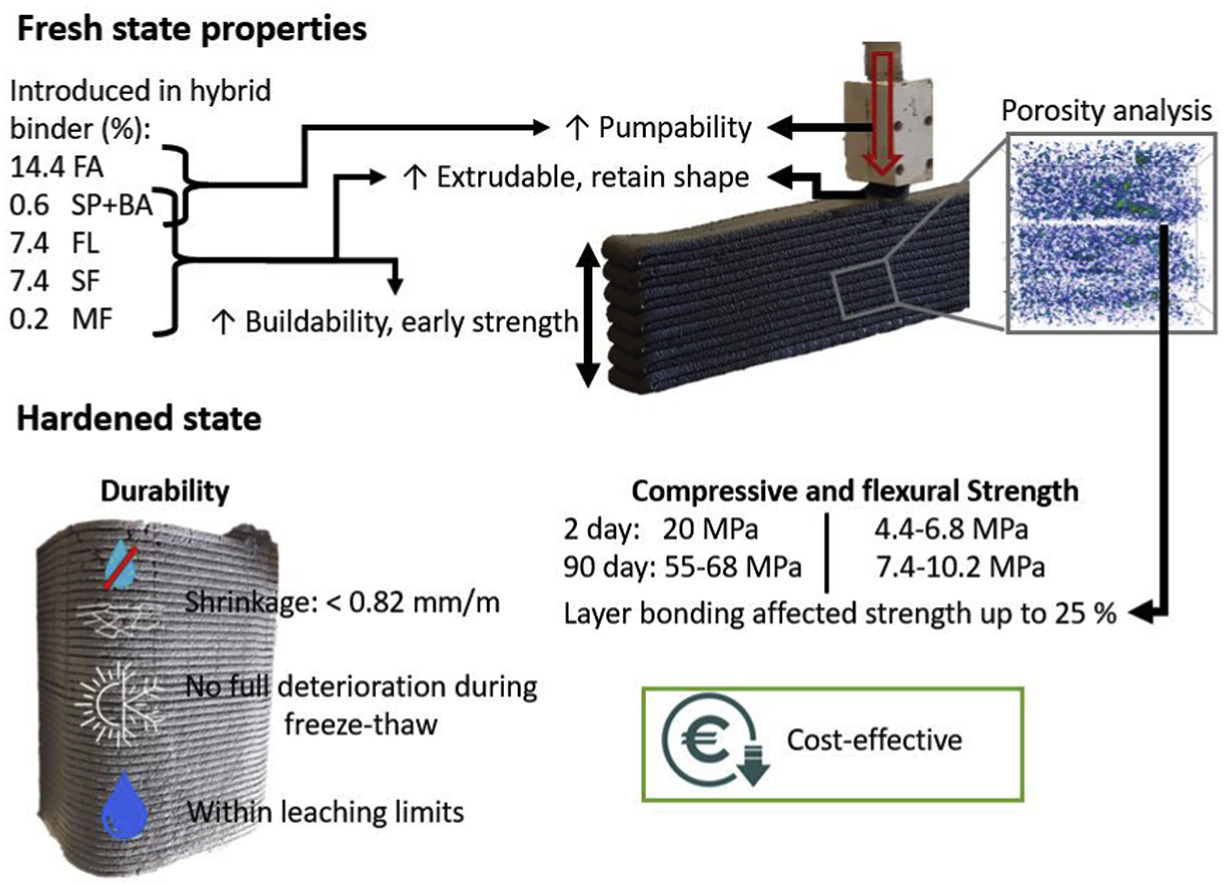

Automation through 3D printing can be a possible technological breakthrough in construction. However, the carbon footprint is not necessarily reduced as the print formulations consist of more ordinary Portland cement (OPC) compared to conventional high-performance mortar. In this study, a hybrid mortar with minor amount of OPC and mainly Fe-rich, low-Ca slag is used for printing several structures, followed by a profound study on the durability properties of the printed material. The hybrid mortar outperformed the benchmark with respect to its compressive strength (80.5 ± 4.3 MPa versus 52.4 ± 1.7 MPa) and drying shrinkage (0.8 mm/m versus 1.3 mm/m). The capillary pores present in the printed hybrid resulted in a lower freeze-thaw resistance. Leaching tests showed that the hybrid binder immobilized heavy metals. The hybrid mortar has a CO2 impact between 164 kg CO2/m3 and 548 kg CO2/m3, and costs range from 129 to 193 euro/m3. This study showed that the hybrid mortar can offer a suitable alternative to 3D-printable OPC-mortars.