Abstract

Abstract

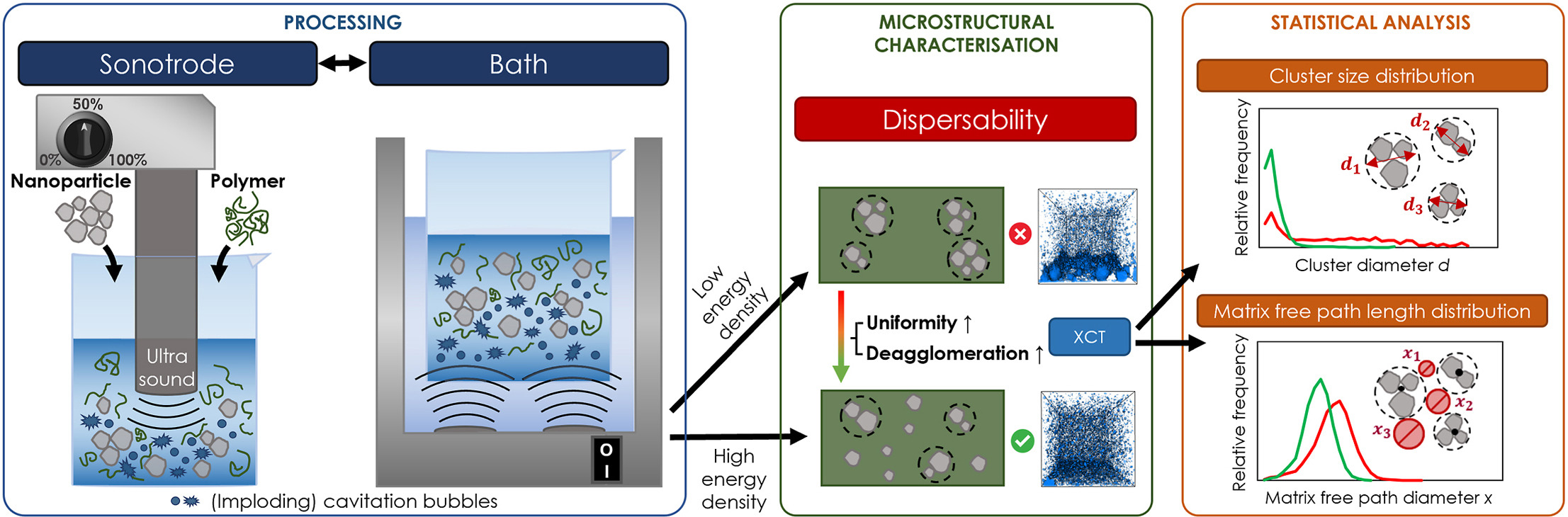

3D nanoparticles are important as reinforcing or functional phase in polymer composite materials; however, an optimised deagglomeration and uniform distribution of these particles is required to fully exploit their nanoscale properties. Classical dispersion methods like shear mixing have proven insufficient, and high-energy ultrasonication, as the preferred deagglomeration method, requires a challenging system-specific optimisation procedure. Therefore, a study was set up to reveal general scaling trends and good practices in developing an ultrasonication procedure for both thermoplastic and thermoset polymer-nanoparticle systems. The ultrasound energy density served as a universal scaling parameter and the higher power densities in the range of 1W/ml achieved by sonotrode ultrasonication were demonstrated to be necessary for complete deagglomeration. For epoxy and barium titanate (BaTiO3) as a below-percolation thermoset model system, an optimal energy density of 120 J/g was observed. Polyvinylidene difluoride (PVDF) and titanium carbonitride (TiCN) were selected as an above-percolation model thermoplastic system for which ultrasonication in suspension at an energy density of 950 J/ml followed by a crucial rotary evaporation step was necessary. X-ray computed tomography imaging has proven to be a powerful characterisation tool in combination with the matrix-free path diameter. This parameter was proposed as a novel parameter for single-parameter quantification of particle dispersibility as opposed to the commonly used and often inconclusive average cluster diameter.

Graphical abstract